News

The Process of Manufacturing Manual Toothbrushes: From Design to Packaging

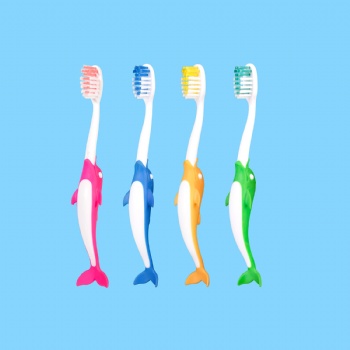

In the world of oral hygiene, manual toothbrushes play a crucial role in keeping our teeth clean and healthy. Have you ever wondered how these essential dental tools are made? Let’s take a closer look at the fascinating process of manual toothbrushes.

Design and Development:

The journey of a manual toothbrush begins with the design phase. Skilled designers work on creating ergonomic shapes and bristle patterns that will effectively clean teeth. They consider factors like grip comfort, bristle firmness, and overall user experience during this stage.

Material Selection:

Choosing the right materials is essential for producing high-quality toothbrushes. Manufacturers typically use materials like durable plastics for the handle and soft, nylon bristles for effective cleaning. These materials undergo rigorous testing to ensure they meet safety and hygiene standards.

Injection Molding:

The next step in the manufacturing process is injection molding. This process involves melting the chosen plastic material and injecting it into molds to form the toothbrush handles. Precision is key in this stage to create consistent and uniform products.

Bristle Attachment:

Once the handles are ready, the bristles are attached. The bristles are carefully arranged in specific patterns to optimize cleaning efficiency. Advanced technology is used to securely anchor the bristles to the handle, ensuring they stay in place during use.

Quality Control:

Quality control is a critical aspect of toothbrush manufacturing. Each toothbrush undergoes thorough inspection to check for defects, bristle integrity, and overall functionality. Any substandard products are removed from the production line to maintain high standards.

Packaging:

After passing quality control, the toothbrushes are ready for packaging. Attention is given to attractive and informative packaging designs that catch the consumer’s eye. Clear instructions on how to use and dispose of the toothbrush are included for customer convenience.

Distribution:

Once packaged, the toothbrushes are prepared for distribution to stores and dental clinics worldwide. Efficient logistics ensure that the products reach their destinations promptly and in optimal condition.

Environmental Considerations:

Manufacturers are increasingly focusing on sustainable practices in toothbrush production. From using recyclable materials to designing eco-friendly packaging, efforts are made to reduce the environmental impact of manufacturing manual toothbrushes.

In conclusion, the process of manufacturing manual toothbrushes is a meticulous and multi-step journey that involves design, material selection, production, quality control, packaging, and distribution. By understanding this process, we gain a greater appreciation for the care and attention that goes into creating the everyday dental tool that helps keep our smiles bright and healthy.

Categories

Contact Us

- +86-027-85787366

- +86-027-85787566

- 13871391583

- info@colzit.com

- vickyzhang1988

- 86-13871391583

售前客服

售前客服