News

A Comprehensive Guide to Toothbrush Factory: Processes, Quality Control, and Innovation

Introduction:

In the fast-paced world of oral healthcare products, toothbrush factories play a crucial role in producing high-quality toothbrushes for consumers worldwide. From the initial design stage to final packaging, these factories undergo a series of meticulous processes to ensure that every toothbrush meets the highest standards of quality and innovation. In this guide, we will explore the inner workings of a toothbrush factory, including the manufacturing processes, quality control measures, and ongoing efforts in innovation.

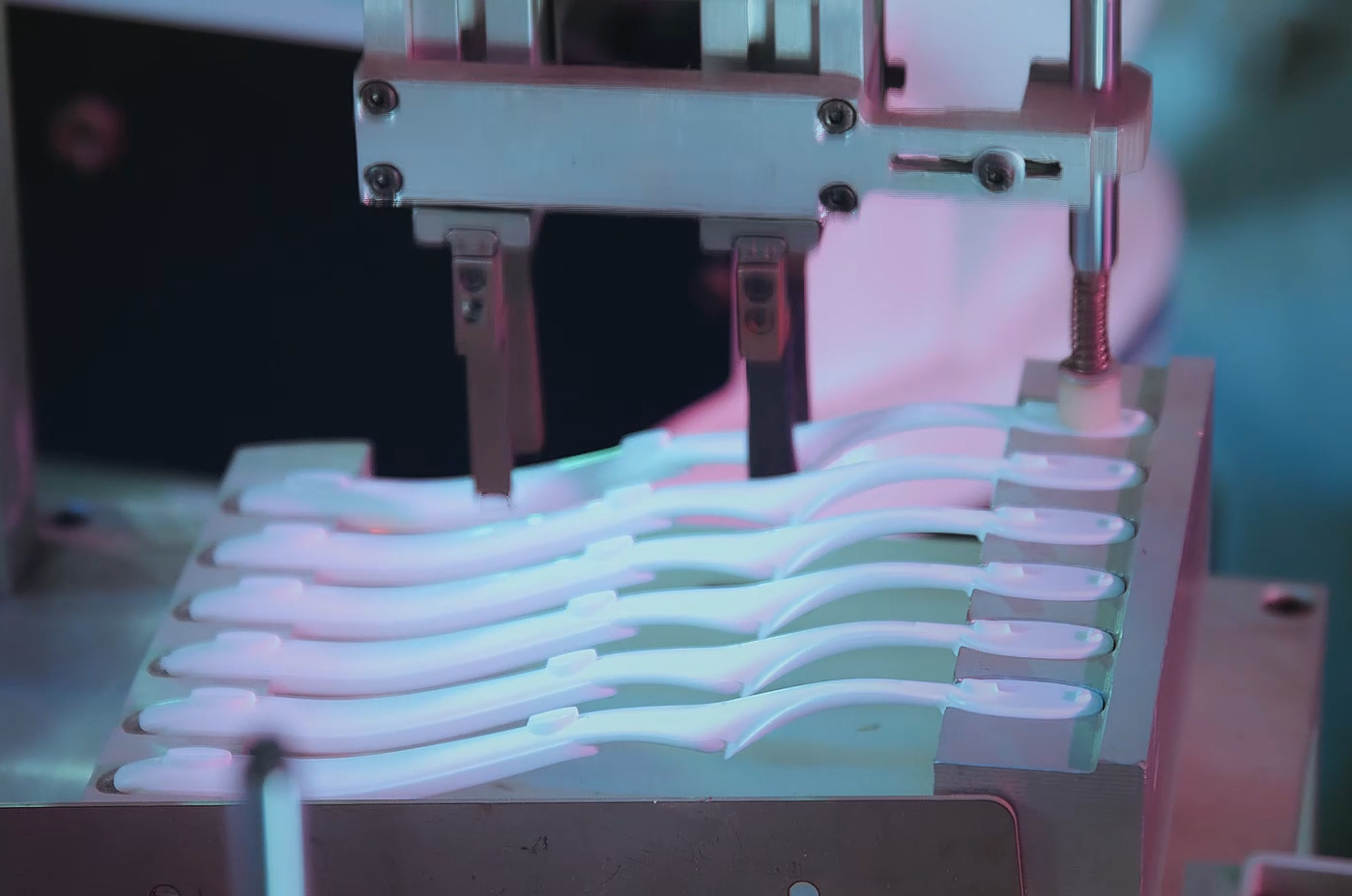

Manufacturing Processes: The production of toothbrushes begins with the selection of high-quality raw materials, such as nylon bristles, plastic handles, and rubber grips. These materials are then carefully inspected and tested for durability and efficacy. Next, the raw materials are fed into automated machinery that molds, trims, and assembles the components to form the final toothbrush product. From injection molding to bristle cutting, each step in the manufacturing process is closely monitored to ensure consistency and precision.

Quality Control Measures: Quality control is a top priority in toothbrush factories to guarantee that every toothbrush leaving the production line meets stringent standards. This involves rigorous testing of bristle stiffness, handle durability, and overall product performance. Random sampling and batch testing are conducted to identify any defects or inconsistencies, ensuring that only flawless toothbrushes are packaged and shipped to consumers.

Additionally, factory employees receive extensive training on quality assurance protocols to uphold the factory's reputation for excellence.

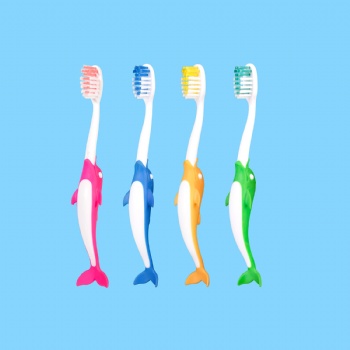

Innovation and Sustainability: Toothbrush factories are constantly striving to innovate and improve their products to meet the evolving needs of consumers. This includes developing eco-friendly materials, incorporating ergonomic designs, and introducing advanced technologies, such as smart toothbrushes with Bluetooth connectivity. Sustainability is also a key focus, with factories implementing energy-efficient practices, reducing waste, and exploring recyclable packaging options. By staying at the forefront of technological advancements and sustainability initiatives, toothbrush factories are shaping the future of oral healthcare products.

Conclusion:

In conclusion, toothbrush factories are at the forefront of producing essential oral healthcare products that promote dental hygiene and overall well-being. Through efficient manufacturing processes, stringent quality control measures, and a commitment to innovation and sustainability, these factories are able to deliver high-quality toothbrushes that meet the demands of consumers worldwide. As the oral healthcare industry continues to evolve, toothbrush factories play a pivotal role in shaping the future of dental care.

Categories

Contact Us

- +86-027-85787366

- +86-027-85787566

- 13871391583

- info@colzit.com

- vickyzhang1988

- 86-13871391583

售前客服

售前客服