News

Choosing the Right Toothbrush Factory: How Size Influences Production

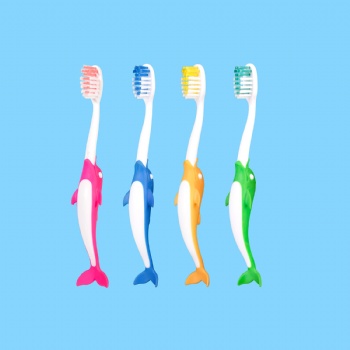

The size of a toothbrush manufacturing facility plays a critical role in the production quality, costs, and overall efficiency. Large-scale factories typically have advanced machinery, greater workforce, and higher production capacity, which can lead to better economies of scale. This allows them to produce large volumes of toothbrushes at lower costs per unit, making them ideal for brands looking for mass production. Furthermore, larger factories often have the ability to produce a wide variety of toothbrush styles, materials, and designs, offering more flexibility for customization.

However, smaller factories can offer certain advantages. They may provide more personalized services and quicker turnaround times for smaller orders. For brands that focus on high-end or niche markets, working with a smaller factory can result in more attention to detail and higher quality control during production. These factories may also be more agile, adapting quickly to design changes or specific product requirements.

Choosing the right factory size depends on your business goals and target market. Large factories are suitable for mass-market brands aiming for high volume at a competitive price. In contrast, smaller factories might be a better choice for luxury brands or those requiring custom designs and smaller production runs. Understanding how factory size impacts production efficiency, costs, and customization options is essential when selecting a toothbrush manufacturing partner.

By aligning your needs with the capabilities of the factory, you can ensure your toothbrush production meets both quality and market demands.

Categories

Contact Us

- +86-027-85787366

- +86-027-85787566

- 13871391583

- info@colzit.com

- vickyzhang1988

- 86-13871391583

售前客服

售前客服